Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

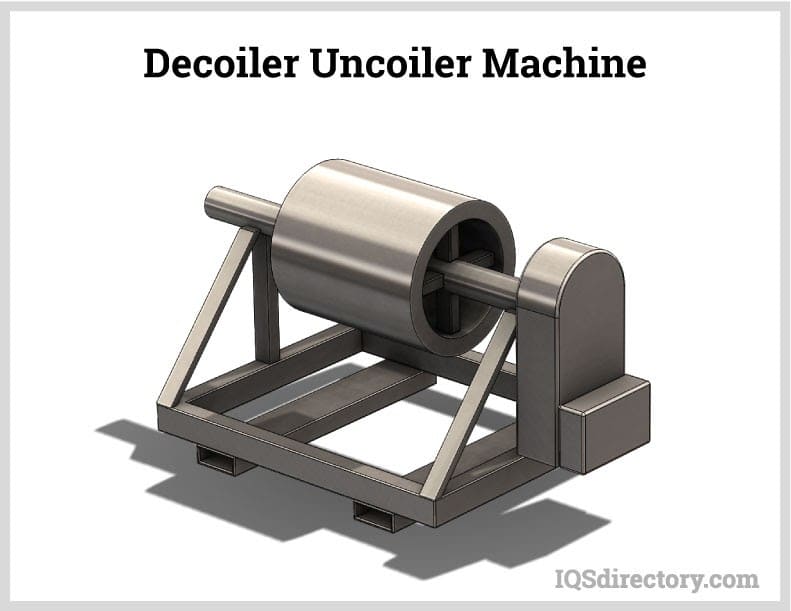

Metal coils may become set during storage and have a tendency to stay coiled and become distorted. To correct the problem, the coil is loaded onto the uncoiler, seen below, and fed through a flattener to remove the coil set. The lead end is trimmed to allow for smooth feeding into the pre-press process.

Part of the pre-press operation may be a tapering of the beginning of the feed coil to make it easier for it to slide into the forming rollers.

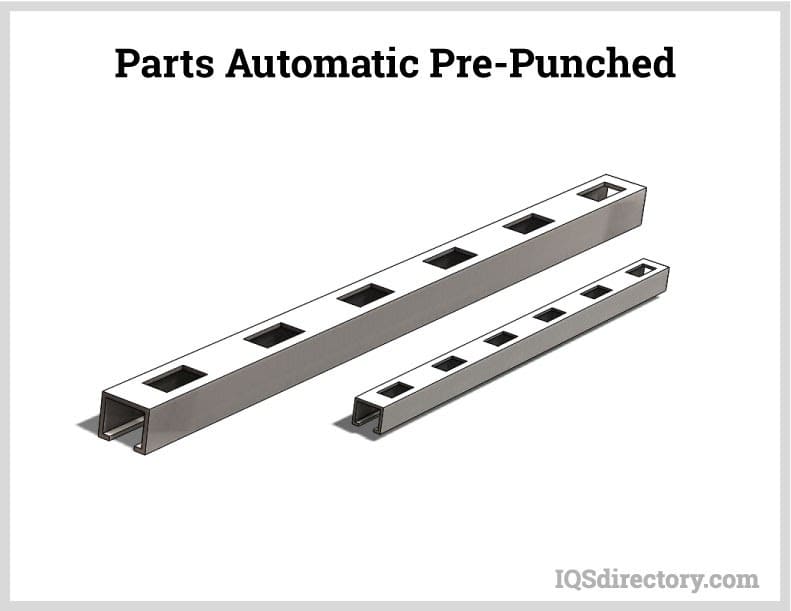

Before the metal from the coil is fed into the roll forming rollers, it may need applications added as can be seen in the image below, which can involve adding slots, holes, or slits.

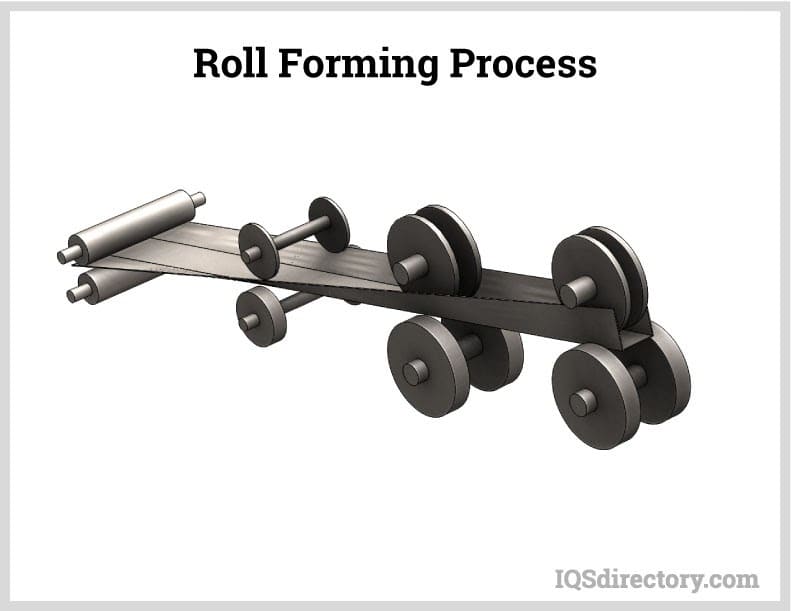

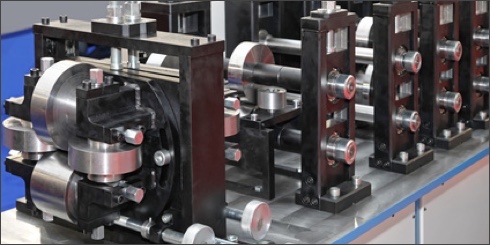

At this stage, the material is progressively shaped. A typical Roll Forming Machine can consist of 10 to 24 pairs of roller die stands. The machine is individually or gang driven to force the ribbon of metal through the rollers that gradually shape it to the dimensions of the flower pattern.

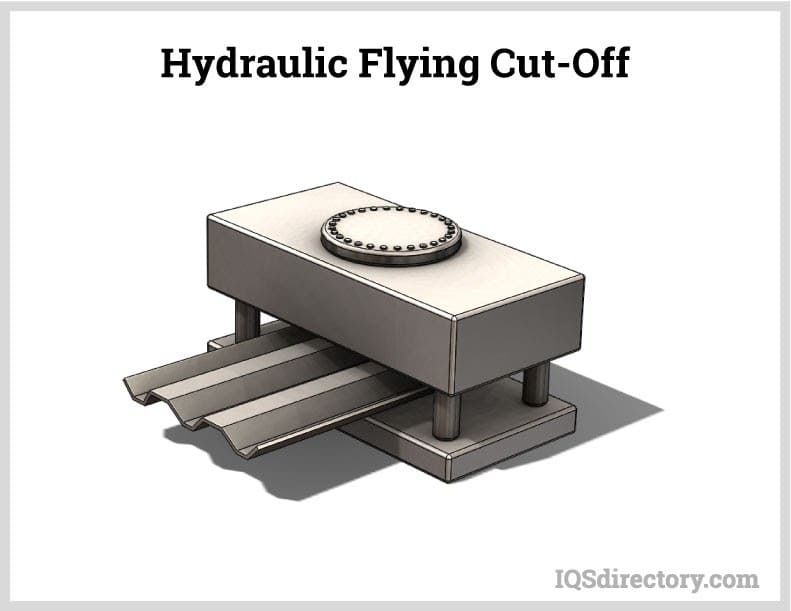

Parts are cut to length as they are in motion, which increases the efficiency and speed of the roll forming process. Once they are cut, they are discharged to a run-out table to be placed for shipment or further processing.

There are a variety of ways secondary processes can be performed. Some can be completed as the part comes off the cutoff, while others may have to be performed at another station.

The image below has samples of some of the listed secondary processes, which include:

With any metal forming process, friction plays an important role, which is the resistance produced when two bodies make contact. It is a means of energy dissipating that causes a rise in temperature where two surfaces meet. The temperature is further enhanced by the speed of the process.

Lubrication is used in the roll forming process to reduce friction between the rolls and metal to prevent tool wear. Friction is a necessary part of the rolling process and an important part of shifting the metal forward between the rollers. It should not be eliminated or reduced below an appropriate level. The need for friction has to be considered when choosing a lubricant.

Roll forming uses fluid lubricants with a low viscosity that include paraffin for non-ferrous metals such as aluminum and copper. Lubricants increase the rate of production, which is determined by the thickness of the material, number of roll stations, and the amount of bending. Below is an example of a roll forming process that uses a chlorine free lubricant.

This Rolling Forming Machine Uses a Chlorine Free Lubricant

(from etna.com)Previous: Benefits and Advantages of Roll Forming Machine

Next: Roll Forming Process

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.